After suffering for 7 years of compressor noise having the 400C inside the cabin, I decided to mount it outside.

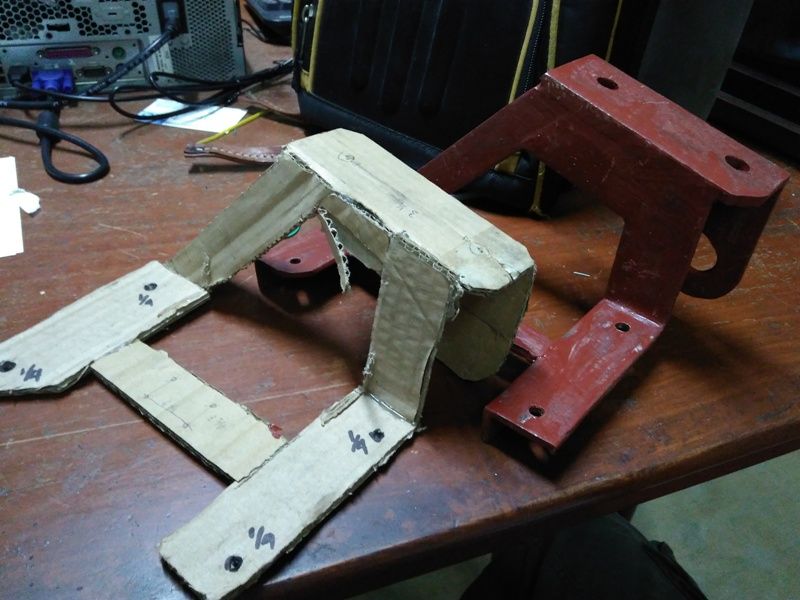

Made a cardboard mockup and then transferred it to steel.

It used the towing hook mounting bolts to mount to the frame.

I was also annoyed that the reed valves in the 400C compressor head seal better than the inline check valve so the leader hose is always under pressure and leaks so the tank goes to almost zero psi overnight.

There is a check valve so why does it leak so much? I hear you ask. Since the leader hose is still pressurized and with the slow leak, the check valve diaphragm would not seal well as there is not enough spring pressure. Low in/out pressure differential won’t let it seal properly especially this old one.

I bought a new one and still the same happens.

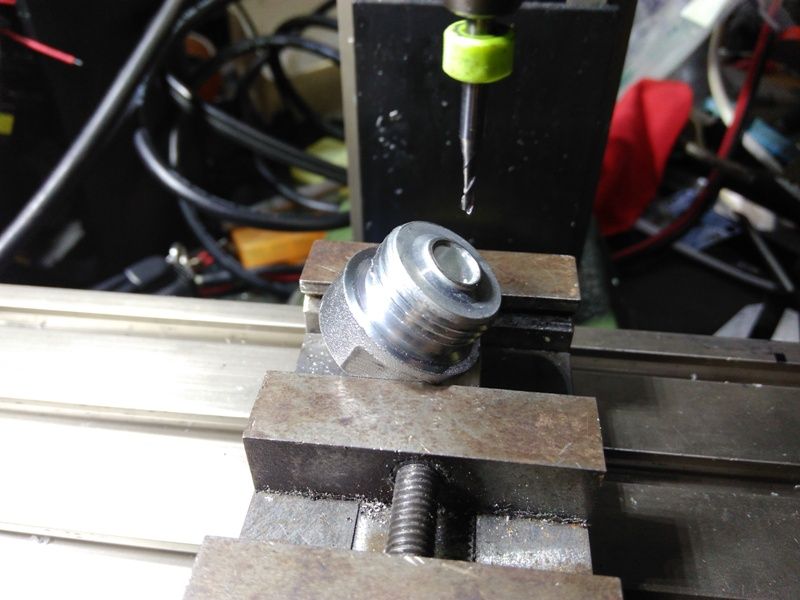

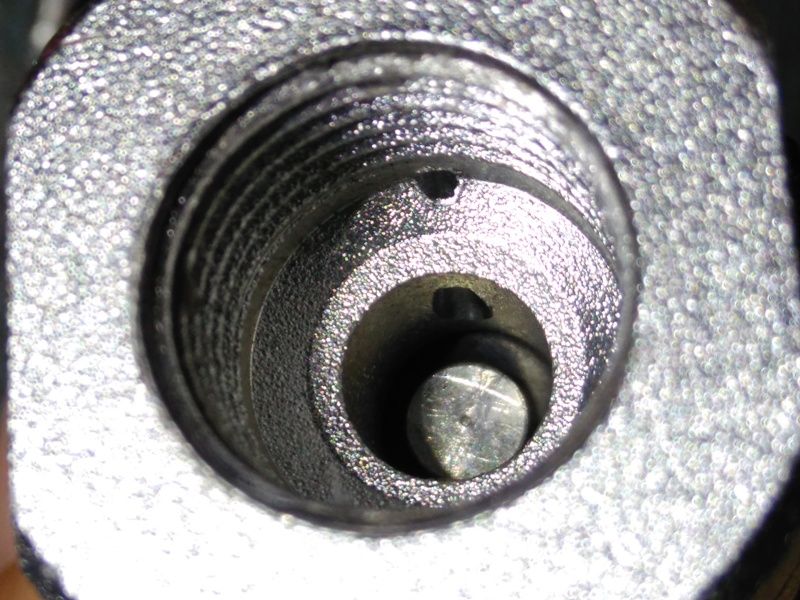

So I drilled the side of the check valve to test my idea. It ports out to the compressor side of the check valve.

Used 4mm tubing to connect it

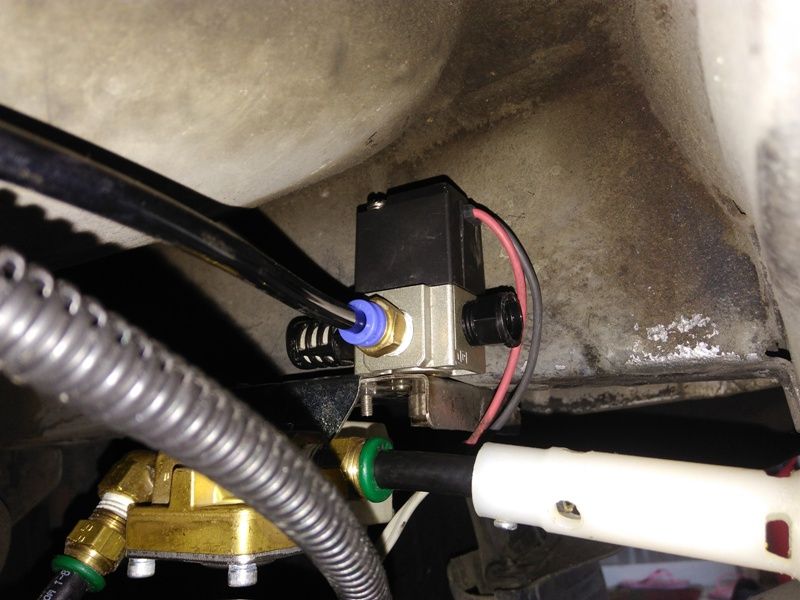

Used a 3 port solenoid valve I got from the scrapper and used the normally open port. Tapped the coil from the compressor power.

When the compressor runs, the solenoid closes and builds up tank pressure. Once the compressor stops, the solenoid opens and vents the leader hose pressure to atmosphere and the check valve seals perfectly. Seems to work like a charm!