I have a friend that wants a K3La in his monte carlo…he already got the horn from me, but now he wants me to install it…got the air system taken care of…but i wanted to know how do most people tap their horns? what size drill bit…then what tap is used?im guessing 1/4"inlet to each bell…but gimme info on tapping the hole.lol…no pun intended…

what are you talking about tapping the horns? are you talking about where people are mounting the horns separately? if so no one is drilling into their horns they are useing special brackets to mount them separately… drilling anything into your horns will most likely kill your horns

x2 what I have seen is ppl using aluminum or steel c channel to separately mount the horns using air line splitters like that one to 5way on ebay but I’d rather fab up my own n not pay 200+ but thts MO

idont see any reason to tap just use the holes that exist in each bell I believe

Please don’t drill out the air inlets on the horn… That will ruin it.

Ditto! It will ruin it.Then you will have to pay some one to fix it such as the Real Horn doc.

Consider the amount of work that goes into my brackets. To make a 5 set of brackets takes me 3 hours, metal isn’t cheap, these are not c-channel as that wont work, brackets are bent on a break, holes are tap’d by hand, they are sand blasted, then powder coated, they include stainless steel hardware, all the fittings, airline, and a cnc’d manifold.

These brackets could be made from aluminum c-channel, but will be very expensive and much thicker then the steel pieces as Aluminum is no where as strong. Aluminum will have be coated as well since it corrodes so easy.

Just to buy the metal, and have it bent costs me 12.00 dollars each. I buy them at 200 at a time.

For what goes into these I don’t think I am charging that much. One single horn bracket from Nathan is over 100 dollars.

Sorry if I am a little defensive as I keep seeing comments about those way to expensive ebay brackets. My comments are not directed at any one person.

I definitely don’t think you charge too much, Curt. If I had a K horn to mount on my Honda, I’d definitely buy some.

got it…i wont drill them…ima tell my buddy about the brackets.its his money…i would like to buy the 2.5" bracket…ima need 3…pm me a price please

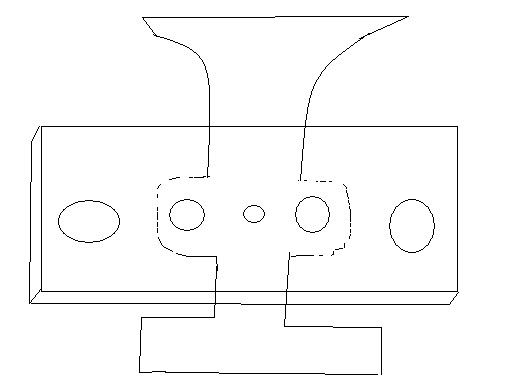

i think ima make my own…like this…1/4" plate…drill 5 holes…and tap it for the air inlet part…

each horn has an o-ring, so you dont have to worry about the seal. i would go a bit thicker than 1/4" so that you have more room for threads. but then again it doesnt have to be 100% air tight, because it will only be seeing air for a few seconds per use.

yea bro by no means was i bashing em i go to school for CNC so i can appreciate the work that goes in…those are actually the best brackets i have seen esp. for production…

Curt,

Would you please PM me a price on a set of 5? I’m going to be getting a K5LL from Jetmann and I’m looking at different mounting options for my '08 Ram 3500.

Thanks.

Kris