I’m sorry its actually a 1/4" port npt. The npt stuff throws my own measurements off. So that’s the biggest port on the tank in which I did remove the relief and now using it as my main feed line.

Terry

I’m sorry its actually a 1/4" port npt. The npt stuff throws my own measurements off. So that’s the biggest port on the tank in which I did remove the relief and now using it as my main feed line.

Terry

Best deal i could find out there for a 3 gallon that has 2-1/2" ports…

Like i said, save a little more and upgrade to something decent.

You will not notice much of any volume of air going to the 5/16" . IMO waste of time and $. And ive wasted enough $ on my multiple horn setups that i try and teach people from my mistakes.

Well for now I only spent 13$ bucks on some fittings and already had all the other parts. Oh and the pressure switch which I would have bought either way. If there is no difference at least my horn is working again. But I do agree with you and in time I can save or sale some things to fund my horn kit.

Thanks for the help.

Terry

Even the upgrade kit keeps the 5/16" lines to the individual horns. That is not where the restriction is. The bottleneck is the main airline and valve.

So keep in mind the ID of the 5/16" tubing is approx 3/16". Measure the ID of your new reducer fitting. Is it close to 5/16"? If so you would benefit from 3/8" or even 1/2" tubing.

It is closer to 3/8" for sure. I see what you mean. Wish I had some 3/8" line but the kit I bought only had the 5/16" stuff. Oh well, if it doesn’t make a change maybe that will motivate me to upgrade to something better. If you don’t mind me asking what do you run in your truck/car/van?

Terry

Yeah I just looked up the ID of a 1/4" schedule 40 nipple - it’s .364".

FYI - the ID of the 1/2" tubing is .375". Sounds like a match made in heaven…lol

I run 5/8" ID air hose for a Nathan K5.

Now that is some serious hose right there. I thought about doing the same to since I have a bunch of 1/2" air compressor hose back when I was in construction. Seems to me it’s easier to work with and would last a lot longer. Is there a purpose for your horns or just to mess around with.

Terry

Oh there’s a purpose! LOL

Laughs, smiles, terror, pranks, ladies…just to name a few

Seriously though, I love the sound of the Canadian tuned K5.

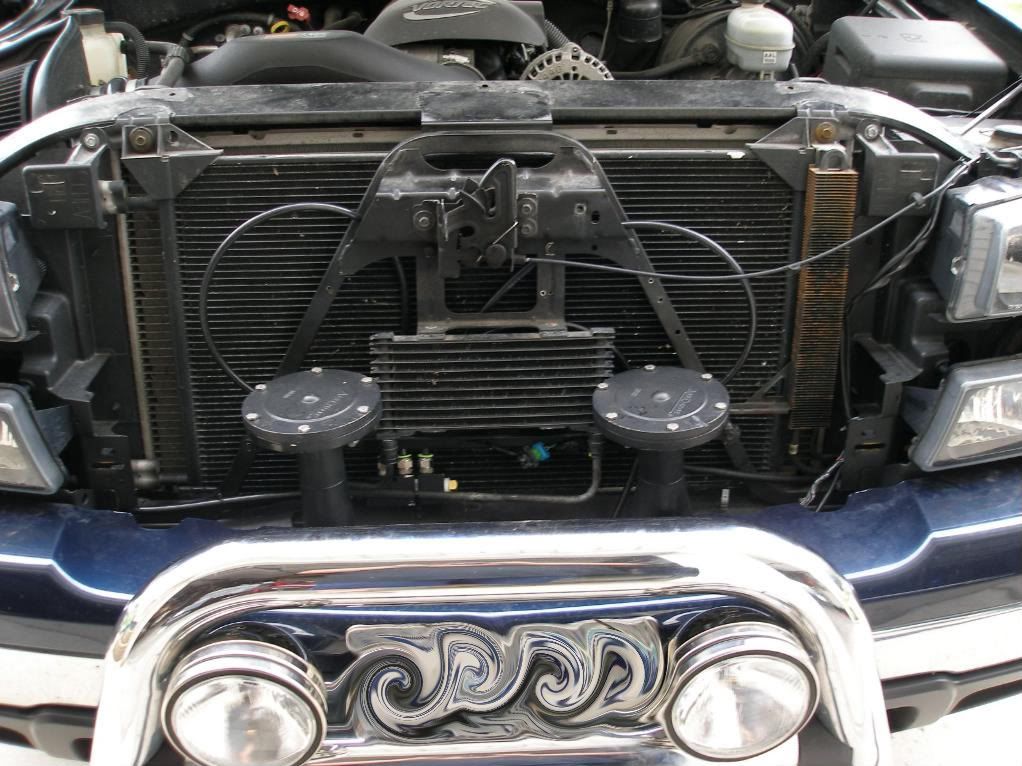

Heres a couple from my setup…

Tube to the right going straight down is 5/8" OD airline… All plumbed with PTC fittings.

Manual GW clone valve controls K3LA

HB4H (shockers) hooked up via 1/2" OD feeding the manifold / splitter which branches to 5/16 line. Controled through push button solenoid in cab or via remote control from up to 3/4 mile away if i choose

Wow dude, that is a lot. Looks killer man. So you have 1 comp for 2 tanks. It must be a very good one then. That’s exactly my plan is to run 2 5 gal tanks but with 2 comp. If I remove my spare tire I have plenty of room. I have my 4 horns mounted under the bed above the spare tire so I can still use the spare and the comp/tank is mounted in the rear fender well on some brackets I made so it sits upright and removable when I need to. I will try to take a couple pics of it.

Terry

Well the compressor i have is a viair 380c.

Its meant for up to 5 gallons only, BUT i have a 150 psi pressure switch in there only … So being that this is a 100% duty 200psi compressor. It can be worked harder that a standard fast fill that is not 100% duty…

Ive been running this setup for a couple years now and have no problems. It isnt as fast at refilling after it gets below 110 psi, but has not failed me yet. The compressor runs every day at least once , but usually 2-3 times. That says a lot about viairs quality!

Disclaimer-- Viairs warranty is only good up to 5 gallons per compressor , but this unit is way out of warranty period. I took a gamble and so far its paying off.

There is a guy on youtube running a 30 gallon tank with 1-viair 380c. And another member on here has one of these 380c’s running a 20 gallon tank…

Like i said , i have been through multiple setups. Thats why i know how expensive a small upgrade in air line is and not effective. Go big and dont regret it later…

Here is what my original 3 gallon tank setup looked like…

This was running a siege engineering 3 trumpet . biggest waste of $ ever…

I have 2 380c’s on an 8.5 gal tank and soon about to add two 5gal tanks:D

Not sure if im going to add more compressors or not yet. But if i do im going with Air Zenith OB2 compressors.

Hoping I will get a lot longer blast time out of the K5:D

Why not just go with the Oasis? It’ll handle all 18.5 gallons

The thought has crossed my mind several times:D

Just havnt quite decided on what I’m going to do on compressors yet. It would be way more simple to have just one Oasis. Just not sure where I would put it since I like to keep my compressors in the dry and cool. Thats why my viairs are in the cab.

Still have time to decide on the new setup:D

Ok guys, got the parts today and had one question. I got a pressure switch that has leads coming off of it. Does it matter where the red and black wire hook up to on it. I would think no but I want to make sure.

Thanks

Terry

Welcome to the forum from nearby SoCal. Air line filters only work when the air is cool enough for moisture to condense. The best location is on the output of a tank because the tank acts like a radiator and cools the air. The longer the compressor runs, the hotter it gets so it takes a long hose for the air to cool down if you want the filter in front of the tank.

Some will use 2 tanks, a small one to cool the air, then the filter, and then a big one for storage.

You still have to drain something whether it’s the filter or tank. Since the tank is larger than the filter it doesn’t have to be drained as often.

Done now. Everything works perfectly. The relief was leaking a little bit so I blasted it out a couple times and it seated nicely. I can’t so for sure without measuring sound but changing the main air line bigger seems to have made it louder. It is ear piercing now. And my air drains a heck of a lot faster than what it did. Either way I am stoked to have them back. The week I went without them it felt like I was naked. Thanks for all the help here.

Welcome to the forum from nearby SoCal. Air line filters only work when the air is cool enough for moisture to condense. The best location is on the output of a tank because the tank acts like a radiator and cools the air. The longer the compressor runs, the hotter it gets so it takes a long hose for the air to cool down if you want the filter in front of the tank.

Some will use 2 tanks, a small one to cool the air, then the filter, and then a big one for storage.

You still have to drain something whether it’s the filter or tank. Since the tank is larger than the filter it doesn’t have to be drained as often.

I see what you mean. Well for now I will manually drain it until I get the true set up I want. I snapped a couple pics since my spare tire was out. Enjoy!!

The comp and tank is nicely tucked under the fender well. Horns are attached using some angle iron and a welder. This is above my spare tire so I still have plenty of room if the spare was out. That is where the 5 gallon tank will go while keeping the 4 horns there and putting the new horns on each side of the rear fenders or up front.

So all the horns fit above the spare tire? As in - you can still keep your spare? That’s nice!

Nice bracketry for the tank too.

Yes sir. I can still fit my spare like normal. So when I get the 5 gallon tank and other horns, the spare will come out and I will fab up some kind of mount for it all in one piece. That was I can take it off at anytime if needed. Thanks for the complement.

Terry