Just wondering what else people have come up with, I wanted to install a backup camera but did not want to do the cheezy plate frame camera or have it visible for a thief to take advantahe of so I came up with this idea and ran with it.

I got a 2 solenoids (1 normally open and 1 normally closed), 1 pressure regulator, 1 air cylinder and the required air line. Then I went to work! This is my finished product.

Ok, so pay no attention to the dirty white paint…

Plate in the normal mode, air cylinder under no pressure.

This is what it looks like dropped, air cylinder under 30psi.

The backup camera is in the center, to the left of it is the air cylinder, return spring and on the far left and right are the 100 watt floods.

What it looks like with the floods on.

The air tank and compressors pushing the 200psi to the train horn.

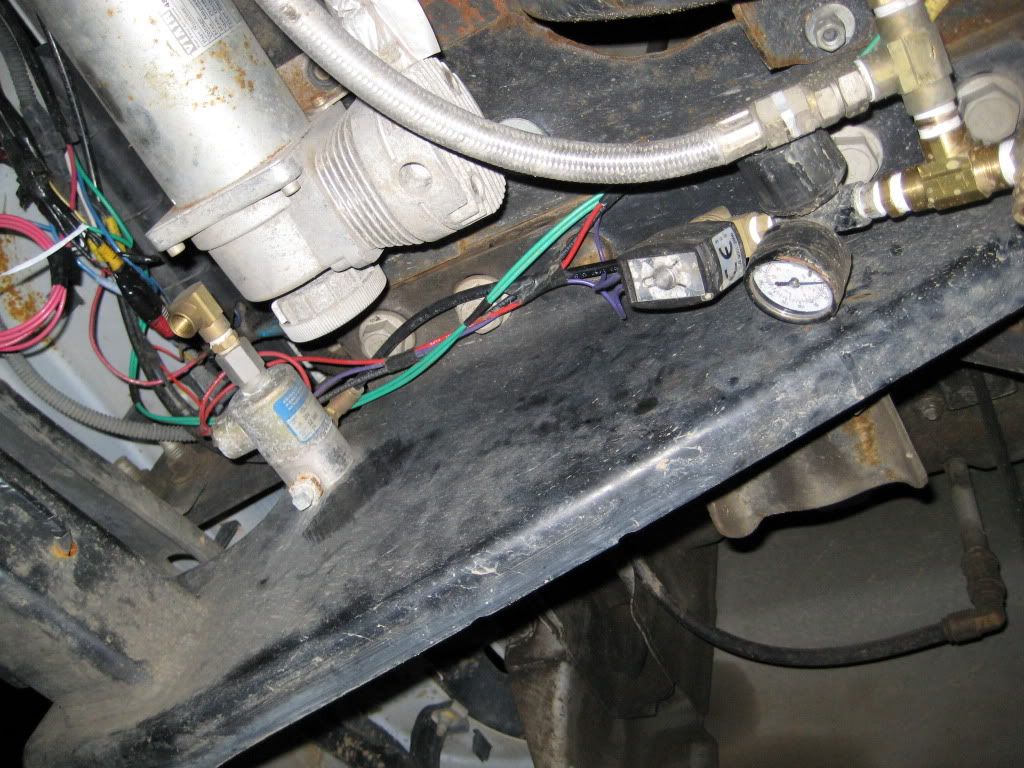

A look @ the pressure regulator (far right) dropping the pressure from 200psi to 30psi for the solenoids (next one to the left which is normally closed) then the normally open solenoid (far left), and on to the air cylinder.

Another look @ the setup from the ground and behind the plate.

Wow those salted roads in Utah over Christmas really made the underside of my truck nasty! Guess I should have cleaned it before taking pictures.

I now use the system for multiple things like inflating tires with the 50’ hose reel I have in the bed or running an impact. The dropping plate is useful for those pesky camera lights or that jack a** that is riding your butt when you feel like blinding him with your hidden back up lights. Lets just say I got really bored one weekend!

I just could not bring myself to buy one of those weak plate flippers with no room behind them for anythhing. When I get some help flicking switches I’ll take some video of how smooth and fast it works.