I have the Viair 444c setup into a 6 gallon tank.

I have 10g wire from the battery to an inline fuse, then to a relay.

10g wire from that single relay back to two more relays, one for each pump.

Everytime the pumps run for more than 2 minutes the 10g wire from the fuse from the battery heats up and then blows the 30amp fuse.

What can I do to keep the hot wire and fuse from heating up and blowing the fuse?

Crude diagram below…

you need bigger wire. i would run at-least 4 gauge from battery and why not just get 40 amp starter solenoid relay and just go off that. i have two 480s and that is how mine is.

Plain & simple - dual 444c can draw 38amps = blown 30amp fuse.

http://viaircorp.com/dual444c.html

You can eliminate the first relay. Just run a dedicated 10ga wire to each of the remaining pair of relays. Put a 30amp fuse on each one - close to the battery.

I’m about to switch to the twin 444C and I’m using an 80A Battery Isolator that I had laying around, which is basically a beefed up relay :).

With the wire getting hot means that you are pretty much running it to its max current rating which will also cause resistance in the wire which is not good besides the risk of it melting and starting a fire! You can get some good quality 4 gauge power wire from a stereo shop, etc. and you will be good to go OR run another 10 ga and use them seperately on each compressor. Remember the fuse like ear2ear stated above!

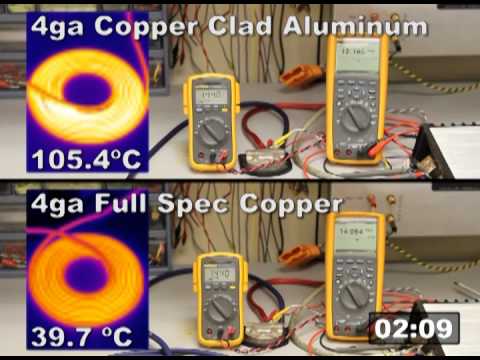

Advice – get pure copper wire when getting that 4ga wire. It’ll be more expensive than CCA (copper clad aluminum), but CCA isn’t as conductive and tends to behave like it’s a wire size smaller than its physical size in terms of conductivity and voltage drop across a given distance. For these reasons, avoid CCA and go pure copper … or if you MUST buy CCA, go a size larger than you would have if you bought pure copper.

I agree with the above, I have 4 gauge ran almost 18 feet from the battery to where my compressors are, from there I have a distribution block which my 10 gauge goes to the relay and them to the compressors. Each compressor has its own power wire to the block. Works like a charm!! Don’t go cheap on your 4 gauge wire, I think I paid like $2.50 a foot, but as mentioned above I do have the aluminum/copper mixed stuff… I have the 4 gauge also fused about 8 inches from the battery with an 80A inline.

I’m not familiar with CCA wire but electrons will take the path of least resistance and they also flow along the outside of a wire strand.

Here’s a solid educational video that shows the reason pure copper (aka OFC … which stands for oxygen free copper) is superior to CCA (copper clad aluminum) – and well worth the extra money. The application in the video is car audio, but what you will see in terms of heat and voltage drop is just as true in any other 12v application.

I was going to jump in earlier and say don’t waste your money on 4ga 100% OFC copper in this application.

If using 8ga and a 50amp fuse, it’s borderline so yeah definitely use OFC pure copper.

But you can easily use CCA wire if using 4ga and 50-80amp fuse.

Also - When reducing wire size such as after a distribution block, fuse each smaller wire.

I have often thought of recommending a cheap dual amp audio installation kit for dual compressors. They come with 4ga CCA wire, fuse near battery, fused distribution block, etc…even an “amp turn-on wire” that could be used as your trigger wire. The problem is that they all come with RCA cables these days. I cannot/have not been able to find one with the RCAs.

I’m all about the 1/0ga pure OFC copper in my setup, but it’s not always required…and I’m kind of a stickler about wiring.