It’s cool I’m curious too. I’ll report back when I get some #'s

Great job. Ive got the same compressors, tank and valve. I haven’t had any problems with anything.

Thanks man! And that’s good to hear!

what size are your airlines??didnt look like 1/2" to me…or maybe its 1/2" OD…i have a 08 like urs.

9gal tank under the passenger side…with 2 480s sitting inside the right fender.where the vents are…5/8" lines.at 200psi.pushing a k3la bolted to the bed.kept my spare

Yeah they’re 1/2" OD. Wish I would have known then what I know now and I would have used 5/8" OD, but at this point I’m not ready to change out all of my airline AND all fittings. I would have liked to put my tank and comps along the frame rails but I have electric steps so that space was taken up.

That’s funny… when I drop my truck off, I tell them where the button is… just to see if one of them will press it ![]()

last time I had mine serviced, I simply turned off the switch to the horns. when my uncle went to get my car back (I was busy with work) he heard the techs honking in the shop while he was waiting in the releasing area. heard some screams, and while they (my uncle and the tech) took a ride around the shop to test drive and make sure there are no problems, the tech honked at his co workers.

I bet they are going to remember my car when it comes back for the next service. :rolleyes:

Okay so I’m going to repaint my K5 when I get home this summer, so I have some questions …

How far down inside the bells did you prime and paint, and are there any tips, tricks, or hints you can share?

What kind of tape did you use to tape off the bells and manifold?

Where did you get the gaskets for the bell to manifold mount?

Kris

I was able to get the paint pretty far down the insides, but after I was finished I wished I had cut access through the tape to inside of the base of the bell. That would have made it much easier to paint inside.

I used 3" blue painter’s tape. Of course any width will work, but the wider tape covers quicker.

I didn’t have any gaskets, all that I had was the o-rings. I’m not even sure that you should use an o-ring AND a gasket together…it seems to me you should only use one or the other because I don’t think an o-ring would make a seal with the gasket in the way. You could buy new o-rings locally, or you can buy o-rings and gaskets direct from the manufacturer here: http://www.microprecisiongroup.com/shop/category.asp?page=2&catid=5&sortby=name

As for tips…

Make the first couple coats of your top coat of paint a light coat. When you first start the top coat it will seem like you aren’t getting very good coverage but that’s ok, just keep adding light coats. If you try to cover them in heavier coats, especially to start, you’ll risk getting runs in the paint. Once you get a couple light coats on them you can start putting it down a bit heavier. If the paint does start to run a bit on you, you can try to wet around the run by painting over it before it starts to dry to try and work the run out. Just be careful not to start another larger run.

Also any over-spray will affect the smooth finish. I found that if I wanted to just touch up a spot and didn’t paint the whole horn again I would have rough spots in the finish from over-spray. If that happened a simple fresh coat of paint would fix that.

The final coat I laid down fairly thick making sure the layer was good and wet otherwise it would end up a bit rough. This happened when I was painting the back caps. I was wondering WTH was going on when they weren’t coming out gloss. After applying a thicker coat I found that they would shine when dry.

Don’t forget to prime the bolts for the back caps if you are going to paint them. I forgot to prime them at first and they flaked horribly when I went to install them. I stripped them back down and primed and painted them and I still had some flaking when I went to install the bolts but not nearly as bad. If you are going to paint the bolts the same as the back caps it won’t be as big of a deal because you could touch them up.

Be prepared to spend a good bit of time on them if you are a perfectionist like me. Hell I probably have 10 - 15 coats on these horns LOL. Taking them in for powder coat would have been a hell of a lot easier and stronger, but I didn’t want to fork out the extra $$.

IIRC I used 2 cans of primer, 3 cans of gloss black, and 4 cans of gloss yellow. I also used 2 cans of spray stripper in the beginning. I sprayed them down with stripper then rinsed them with water. Then I sprayed whatever paint was left with stripper again and used a wire brush to remove it then rinsed them.

Let me know if I can help with any other questions. Good luck and if you can, give us some before / after pics!

Jeff,

I’m used to painting small items from my experience with R/C cars and trucks, but this is exactly what I needed to know. Thanks for posting it!

Kris

Sure no prob! I took from the community while I researched my project and it’s time to give back!

Hey Jeff I will be ordering my stuff soon can you walk me through what you would change? You can email me at steeda50mustang88@comcast.net Just put train horns in the subject. I can call you if that is easier probably better for me. Mine is an 08 and I’m thinking the tanks between the frame rails and the outer body.

After you sprayed your horns with the napa paint stripper how long did you wait before you began to scrap it off and what did you use to scrape the paint off. I also was wondering if you used a low mount manifold or a high mount manifold with your horns.

I used Jeff’s example for the restore of my K5.

Napa Paint Stripper in the aerosol can works great, and I’m using an automotive detailing brush kit to remove the gunk after the stripper is done bubbling. I was on my sixth can before I had to stop and return from vacation, so I do have a bit more work to do. I was using the plastic bristle brush from the kit since the other two brushes are metal and I was afraid of using them and damaging the bells.

For the stubborn spots I used, of all things, the stardard AP brush from an M-16A2 cleaning kit. It has both short and long bristles, and it cleans up quickly for reuse. I used the short bristle side for the stubborn parts and tight spots and the longer bristle side for detail work too large for the smaller brush end, but still needed a smaller brush than the one from the automotive detailing kit. I got a deal on them through an online retailer so I have tons of them around the house.

So far it’s looking good. Another can or two of stripper this coming summer, then primer and paint, and I’ll post some pics of it up.

Kris

Sorry Skip, I haven’t been on here in a while. I don’t think there is anything I would change in my setup, I love it. If you can fit the tank(s) on the frame rails that’s great. I couldn’t because I have electric steps which retract up under the doors. Any other ?'s just ask, I’ll try to check back here more often. If nothing else I’m sure one of the guys here can help! Good luck!

Like Kris said, I just waited about 5-10 min after it stopped bubbling and finished doing it’s job. I used a regular 'ole steel wire brush on mine and a green scouring pad for the hard to reach places. Sprayed it off with water and then applied paint stripper again on any paint that remained and scrubbed some more. The paint on mine came off pretty easy, but I’m sure the ease of removal depends on how old the paint is, how thick it is, and if primer was used in the past.

I used a low mount. The high mount would have protruded lower beneath my truck than I wanted.

Skip, I may have mentioned this previously somewhere, but the one thing I would do different from the beginning is use Rector Seal 5 to seal the threads on your fittings instead of Teflon tape. I was having a time getting the tape to seal completely but after switching to RS5 I have no leaks.

very nice install. Yeh im running the 1/2" OD line that came with the kit as well. I wondered that too about people using the 5/8"OD line.

From the manufactureer of Nathan Airchime:

[COLOR=black]The standard K-3LA three chime consumes 75 SCFM blowing at 100 psig, 96 SCFM at 150 psig and 125 at 180 psig.[/COLOR]

[COLOR=black][/COLOR]

[COLOR=black] [/COLOR]

[/COLOR]

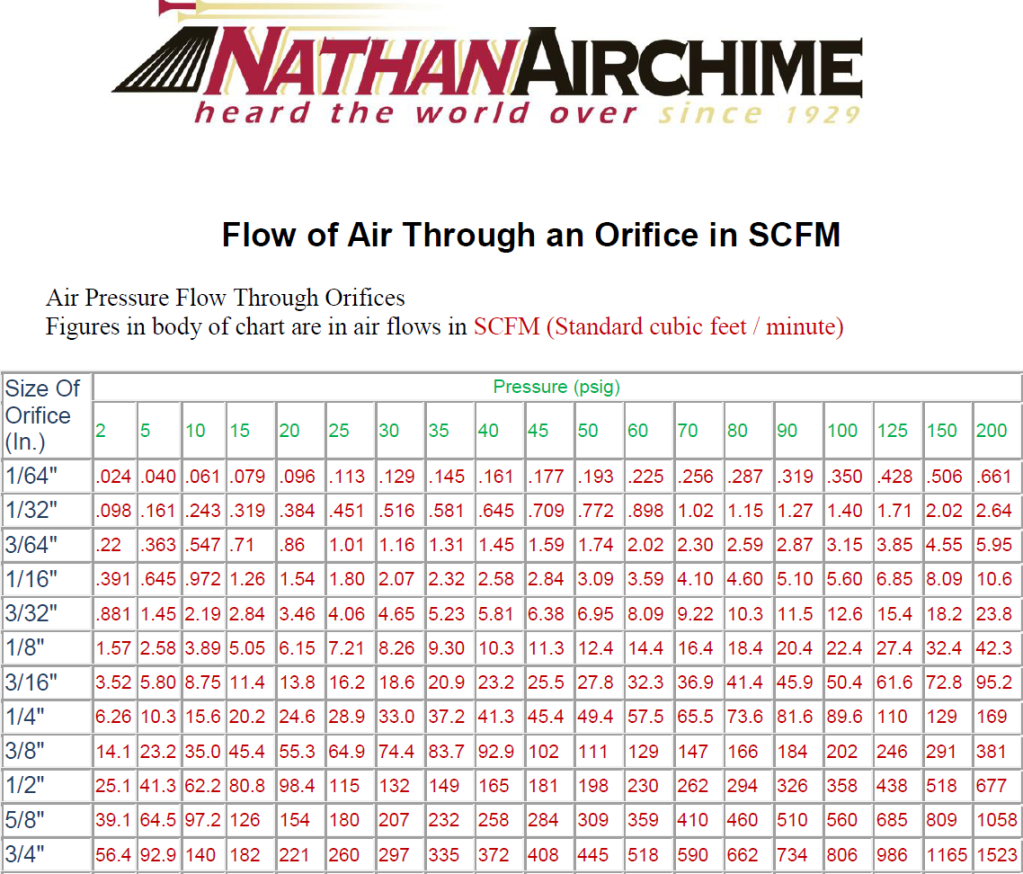

So the way i interpret it is…your putting out 291 SCFM with your 3/8"ID airline. This is more SCFM then the horns consume, so 1/2"OD 3/8"ID is plenty sufficient. Thats what i have on my set up.

Anyone agree/disagree??

Great install. I too have heard about people using 5/8"OD airline. I am using the same as you, 1/2"OD 3/8"ID from the kit

From the Manufacturer nathan airchime:

[COLOR=black]The standard K-3LA three chime consumes 75 SCFM blowing at 100 psig, 96 SCFM at 150 psig and 125 at 180 psig.[/COLOR]

So the way i interpret it from the graph (hope you can see it) is a set up like yours with the 3/8"ID airline puts out 291 SCFM. This is obviously more then what the horn consumes so that should be plenty sufficient. Anybody agree or disagree???

Really cool Truck too

Sounds logical for a K3 with stock 1/8" orifices.

If you’re comparing orifices (LOL) you should be looking at the ID of the fittings or whatever the bottleneck is in your system.